Production and logistics

Production

Logistics

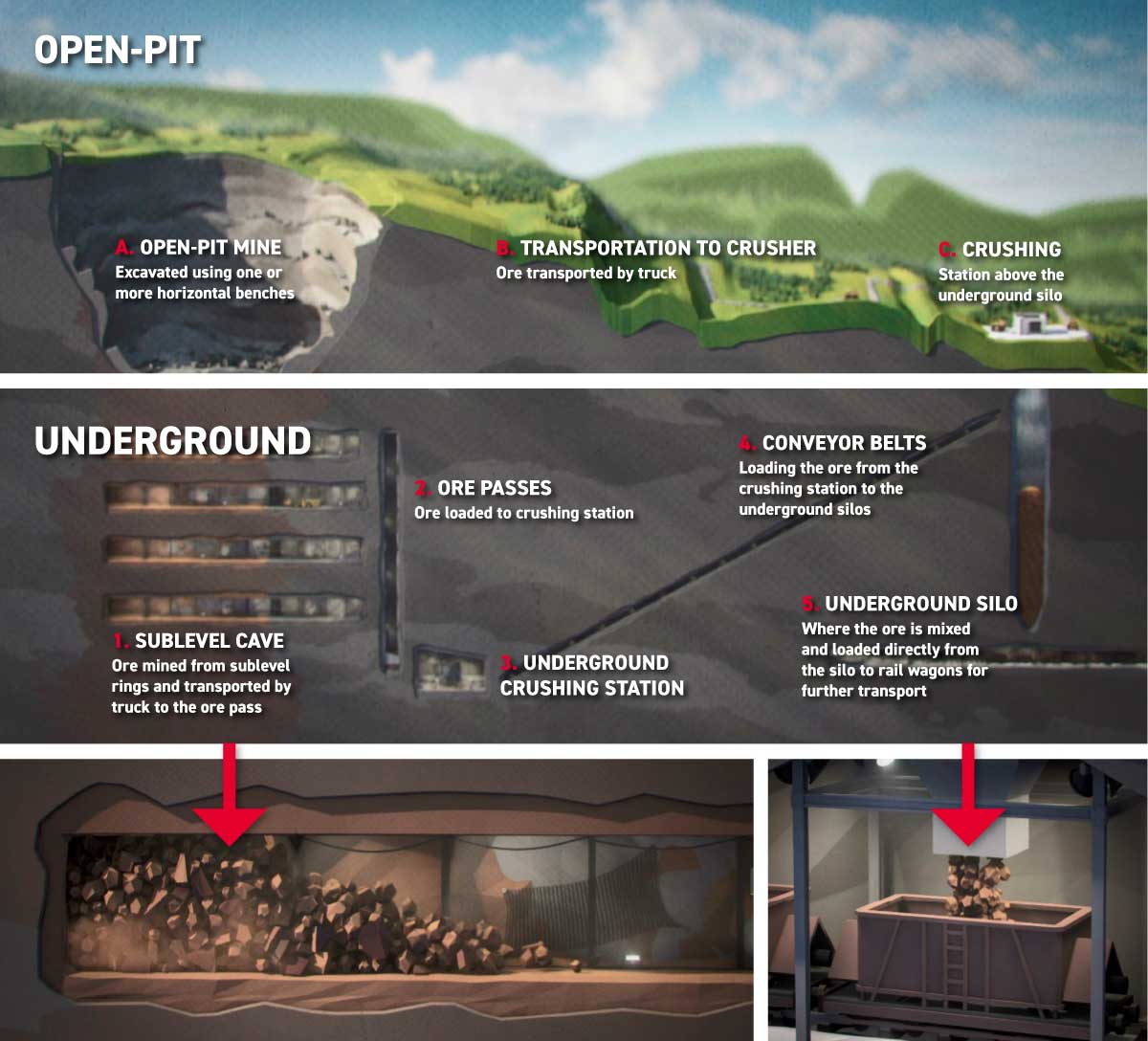

ORE LOADED DIRECTLY FROM SILO TO RAIL WAGONS

Unique and efficient process using gravity to load ore directly from underground silos to rail wagons.

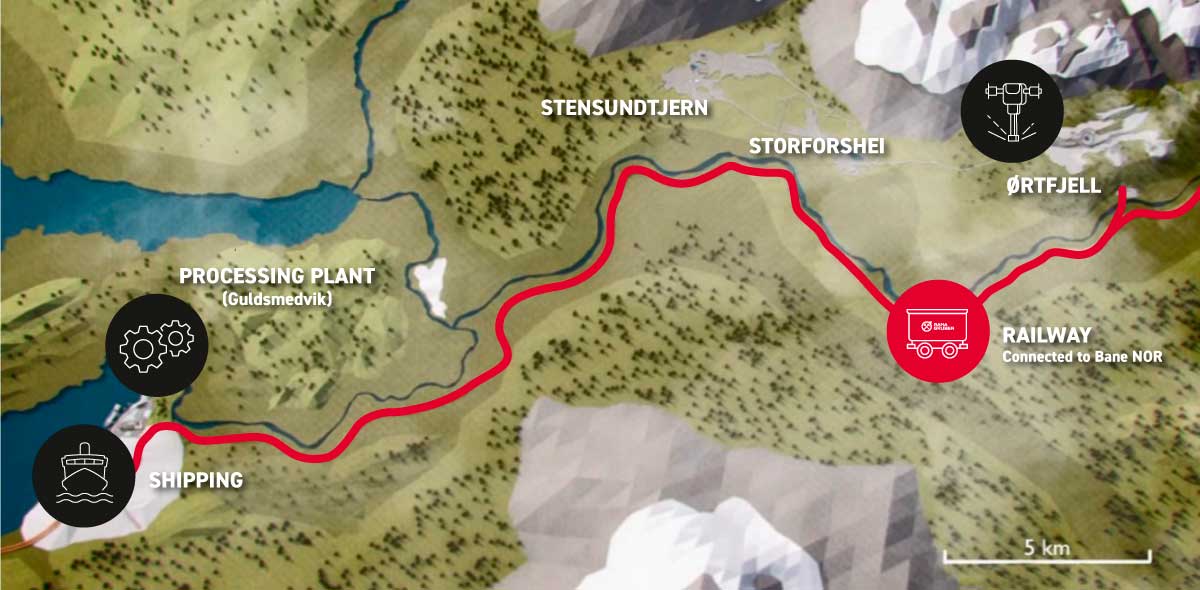

RAILWAY CONNECTED TO PUBLIC RAILWAY

Fully loaded rail wagons are connected directly to the public railway (Nordlandsbanen) and move to the processing plant. The processing plant is located lower in the landscape than the mine, enabling a transportation of iron ore that requires minimal amounts of energy. Railway maintenance is covered by BaneNor and Spordrift.

SHORT DISTANCE TO PROCESSING PLANT

Very short transport distances, as the processing plant is located only ~35 km from the mines.

PROCESSING

Integrated processing plant at the shipping location. Highly cost-efficient operations.

LOADING

Products loaded on vessels at Rana Gruber’s own ice-free port terminal. Most products are sold to customers free on board.

SHIPPING AND TRANSPORT

Every month, 2-3 Panamax vessels are loaded with hematite, and 2-3 short sea vessels are loaded with magnetite. The iron oxide pigments from Colorana® are packed into bags and placed on pallets for dispatch via truck or a combination of truck and rail transport to the final customer.